Overview

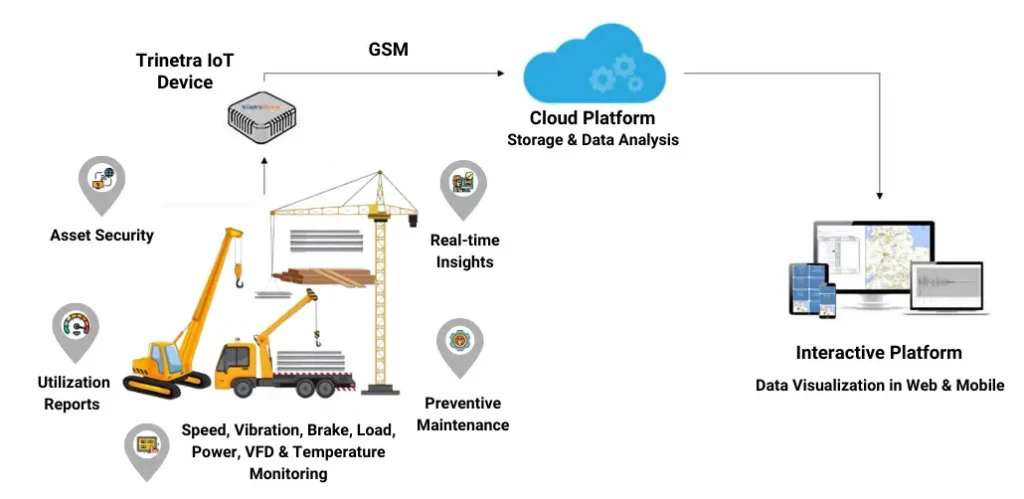

Crane Monitoring Solutions empower businesses with state-of-the-art IoT technology to optimize crane operations. By integrating advanced hardware, wireless sensor networks (WSN), and cloud-based analytics, our solutions provide unparalleled visibility and control over material handling equipment. Whether you are managing indoor cranes such as EOT, gantry, or bridge cranes, or outdoor systems like tower or mobile cranes, our monitoring solutions ensure seamless operation, enhanced safety, and increased productivity.

Key FEATURES:

Real-Time Monitoring: Gain continuous insights into crane performance and operational parameters to ensure efficiency and reliability

Cloud Analytics: Harness powerful data-driven analytics for predictive maintenance, performance optimization, and informed decision-making.

Enhanced Safety: Monitor critical safety parameters and ensure compliance with safety standards, reducing risks to personnel and equipment.

Mobile Integration: Access crane data anytime, anywhere, through user-friendly mobile applications for streamlined operations.

Data-Driven Insights: Provides actionable insights through advanced reporting and analytics, supporting decision-making and strategic planning.

Comprehensive Traceability: Tracks the entire lifecycle of inventory items, from receipt through to dispatch, ensuring full visibility and compliance with industry standards.

Revolutionizing Material Handling with IoT-Enabled Cranes

Raygain transforms traditional cranes into intelligent, IoT-enabled lifting systems designed to meet the most demanding operational challenges. From standard models to fully customized designs, our solutions integrate advanced technology to enhance performance, improve safety, and streamline operations.

Our IoT-enabled systems bring automation and intelligence to overhead cranes through cutting-edge Wireless Sensor Networks (WSN). Envision a safer workplace, optimized workflows, and seamless operations—all achieved with Raygain’s innovative solutions.

Every crane we deliver leverages the latest advancements in software and engineering, providing state-of-the-art functionality from the outset. Designed with scalability in mind, our systems ensure easy modernization to keep your equipment aligned with evolving technology. Whatever your lifting requirements, Raygain offers the ideal solution. Contact us today to discover how our automated cranes can elevate your operations.

KEY BENIFITS OF CRANE MONITORING

- Enhanced Safety & Productivity: Leverage WSN-IoT for safer, more efficient operations.

- Real-Time Monitoring: Access real-time performance insights and generate comprehensive operational reports.

- Cloud-Based Analytics: Utilize data-driven analytics for strategic decision-making and process improvement.

- Optimized Logistics: Streamline transportation and workflow planning for maximum efficiency.

- Reduced Operator Fatigue: Minimize manual strain through intelligent automation.

- Cost Efficiency: Lower operational costs and improve inventory management efficiency.

Challenges in Crane Monitoring

- Limited Real-Time Insights

- Absence of continuous performance tracking hinders early issue detection and operational efficiency.

- Safety Compliance Gaps

- Ineffective monitoring of critical parameters like load limits and tilt angles increases safety risks and non-compliance.

- Unplanned Downtime

- Reactive maintenance approaches lead to unexpected breakdowns, disrupting operations and increasing costs.

- Data Silos

- Fragmented systems and poor data integration limit access to actionable insights and predictive analytics.

- Environmental Constraints

- Outdoor cranes face connectivity issues and wear from harsh conditions, impacting monitoring accuracy.

- Complex Retrofitting

- Upgrading legacy equipment with modern monitoring solutions often involves technical and financial challenges.

- High Operator Dependency

- Manual operations increase the risk of errors, operator fatigue, and inefficiencies.

- Integration Barriers

- Lack of seamless compatibility with existing automation systems complicates implementation and disrupts workflows.

- Insufficient Alerts

- Delayed or missing notifications for critical faults reduce response times and escalate risks.

- Customization Limitations

- Standard solutions may fail to address unique industry or operational requirements effectively

Indoor Crane Monitoring and Preventive Maintenance Parameters

- Motor Voltage and Current Monitoring

Monitors hoist, cross travel, and long travel motor health. AI-driven algorithms identify anomalies early, enabling preventive maintenance to avoid costly breakdowns. - Motor Temperature Monitoring

Safeguards against motor burnout by issuing timely alerts when temperature thresholds are exceeded, preventing expensive repairs. - Hoist Motor Vibration Analysis

Tracks long-term wear and tear. AI-based insights notify users when preventive maintenance is necessary to mitigate potential failures. - Crane Operation Usage Monitoring

Captures operational data such as button presses and limit switch activations to evaluate usage, efficiency, and remaining service life. - Motor CDF (Cyclic Duration Factor)

Tracks CDF usage to ensure motor operations remain within safe parameters, issuing alerts when limits are exceeded. - Load and Overload Monitoring

Uses sensors to monitor load conditions, ensuring safe crane operation and preventing overloading risks. - Motor Brake Fault Monitoring

Monitors brake air gaps to detect safety risks and prevent load drops due to brake malfunctions. - SCADA, VFD, and PLC Integration

Interfaces with automation systems to analyze control parameters, fault conditions, and overall system status for in-depth insights. - Safe Design Working Period (SWP)

Utilizes operational history, load conditions, and CDF to calculate remaining service life, offering a clear understanding of crane longevity. - Crane Rope Fault Detection

Identifies slack ropes and provides instant alerts to mitigate safety hazards such as load drops.

Comprehensive Remote Crane Monitoring Solutions

Raygain’s Remote Crane Monitoring System delivers a complete IoT-enabled solution by integrating cloud analytics, mobile applications, and advanced hardware sensors. Whether retrofitting existing equipment or deploying new systems, our technology enhances the performance of indoor cranes—such as EOT cranes, double/single girder cranes, gantry cranes, bridge cranes, JIB cranes, and HOT cranes—as well as outdoor systems like tower cranes, mobile cranes, telescopic cranes, and container cranes.

Empower your operations with Raygain’s next-generation solutions. Reach out to us today to learn more!

Title Comprehensive Crane Monitoring and Preventive Maintenance Solutions

Raygain provides state-of-the-art Crane Monitoring and Preventive Maintenance Systems to ensure superior safety, efficiency, and reliability in both indoor and outdoor crane operations. Utilizing advanced sensors, AI-powered analytics, and cloud-based monitoring, our solutions deliver actionable insights that optimize crane performance while minimizing downtime and maintenance expenses.

Cloud-Based Data Analytics, Reports, and Alerts

Our cloud-enabled analytics system offers:

- Operational Dashboards and Reports: Gain daily and weekly operational insights delivered via email or accessible through a web interface.

- Real-Time Alerts and Alarms: Receive instant notifications through email or SMS for quick corrective actions on critical parameters.

Indoor Crane Monitoring and Preventive Maintenance Parameters

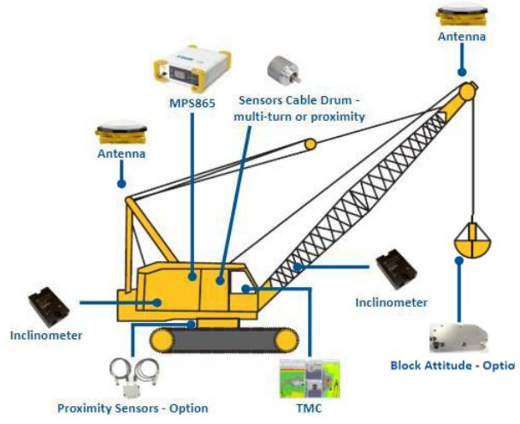

- GPS Tracking

Tracks crane location in real-time, enhancing fleet management and operational oversight. - Speed Monitoring

Monitors crane speed and alerts users to over-speeding incidents, ensuring compliance with safety standards. - Operational Data Collection

Consolidates sensor data to assess usage patterns and predict maintenance needs effectively. - Safe Load Indicators

Detects load angles, weights, and ground radius, providing alerts for unsafe lifting conditions. - Crane Angle and Tilt Monitoring

Tracks crane tilt and angle, issuing alerts when safety thresholds are crossed. - Accident and Vibration Monitoring

Monitors vibrations and accidents in real-time, enabling immediate corrective actions. - Hydraulic Motor Pressure Monitoring

Uses AI algorithms to detect hydraulic motor anomalies, offering early alerts to prevent system failures.

CONCLUSION

Raygain redefines crane operations with advanced IoT-driven monitoring and preventive maintenance solutions. By enhancing safety, optimizing performance, and reducing downtime, we empower businesses to achieve operational excellence. Trust Raygain to deliver cutting-edge, customizable solutions that elevate your material handling efficiency and drive long-term success.

With Raygain’s cutting-edge solutions, your business gains unparalleled control, safety, and operational efficiency. Contact us today to explore how we can transform your crane management systems.