Overview

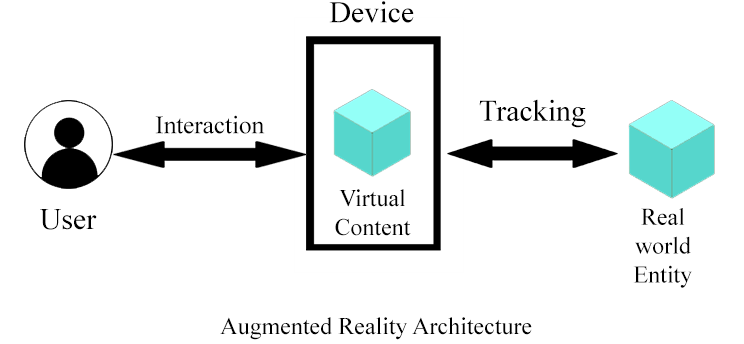

Augmented Reality (AR) is an advanced technology that overlays digital content—such as images, videos, and data—onto the physical environment in real time. By integrating virtual elements with the real world, AR enhances user experiences and interactions, offering a seamless blend of physical and digital information.

In corporate applications, AR can be utilized for a wide range of purposes, from remote assistance and training to product visualization and data-driven decision-making, enabling businesses to improve operational efficiency, enhance customer engagement, and streamline workflows.

Key FEATURES:

Real-Time Data Overlay: Seamlessly integrates digital content, such as graphics, videos, and data, into the real-world environment in real-time, enhancing decision-making and user interaction.

Interactive Experience: Enables users to interact with both physical and virtual elements, creating immersive and engaging experiences for improved training, marketing, and product visualization.

Remote Assistance & Support: Provides real-time remote support by overlaying instructions or guidance directly onto the user’s view, facilitating efficient troubleshooting and maintenance.

Enhanced Visualization: Allows businesses to visualize complex data, products, or systems in a more intuitive manner, aiding in design, prototyping, and customer presentations.

Seamless Integration with IoT: Connects with Internet of Things (IoT) devices to provide live, actionable insights and real-time monitoring, improving operational efficiency.

Improved Training & Simulation: Offers interactive training solutions by simulating real-world scenarios, providing safe, cost-effective, and scalable learning environments.

FUNCTIONAL SPECIFICATION

· Augmented Reality (AR) in Industrial Environments

Augmented Reality (AR) offers transformative potential in Industry 4.0, providing innovative solutions to optimize processes across various industrial domains. Below are key areas where AR can drive operational efficiency and enhance productivity:

· Manufacturing

AR significantly enhances product design and development by enabling real-time monitoring of production processes. It helps identify design flaws early in the development cycle, reducing the need for physical prototypes and accelerating production timelines. This leads to considerable time and cost savings, ensuring a smoother transition from design to manufacturing.

·Support & Maintenance

AR empowers engineers with the ability to receive remote support during production and maintenance activities. This facilitates more efficient troubleshooting, allowing specialized personnel to provide guidance from anywhere. By making complex instructions visually accessible, AR enhances the accuracy and speed of maintenance processes, reducing downtime and improving operational efficiency.

·Logistics

In large facilities such as warehouses or manufacturing plants, AR provides clear, visual navigation, enabling workers to quickly locate materials, products, or equipment. This is especially useful in complex environments, ensuring that employees can navigate unfamiliar spaces with ease and efficiency, enhancing operational flow and reducing time spent on manual searches.

·Sales & Presales

AR revolutionizes sales and marketing efforts by providing dynamic, interactive product demonstrations. It allows companies to showcase complex products or machinery virtually, eliminating the need for costly physical samples. Through AR, potential clients can engage with virtual product models, making it easier to understand technical specifications and visualize how products fit their needs, all while enhancing customer engagement.

· Workplace Safety & Protection

AR plays a critical role in improving workplace safety by visually highlighting potential hazards and emergency procedures in real time. By providing on-site, interactive safety instructions and evacuation routes, AR ensures that workers are better prepared to respond quickly to emergencies, fostering a safer working environment and reducing accident risks.

·Implementation Process

The AR solution implementation involves providing AR glasses connected to a Wi-Fi network, which will be worn by personnel stationed at the end of the production line. These glasses will capture images of products in real time, transmitting them to a cloud server for inspection of potential production defects or material issues. The cloud server will process the data, and the on-site worker will receive immediate feedback and necessary information to address any identified concerns. This streamlined process enhances efficiency and minimizes errors, ensuring superior quality control throughout production.

CHALLENGES FACED WITHOUT AGUMENTED REALITY

- Operational Inefficiencies: Traditional processes lack real-time data integration, leading to delays and reduced productivity.

- Limited Training Effectiveness: Conventional training methods fail to simulate real-world scenarios, resulting in longer onboarding and higher costs.

- Suboptimal Customer Engagement: Static presentations and outdated strategies fail to capture customer interest and drive conversions.

- Extended Downtime: Inefficient troubleshooting and maintenance methods increase downtime and operational costs.

- Workplace Safety Gaps: Lack of real-time hazard visualization and safety instructions increases risks and accident potential.

- Resource-Intensive Product Development: Dependence on physical prototypes and manual processes leads to higher costs and prolonged timelines.

- Missed Opportunities for Innovation: Limited scalability and interactivity hinder businesses from meeting modern demands and staying competitive.

BENIFITS OF agumented reality

- Reduced Development Time: AR facilitates more effective planning and analysis, enabling quicker decision-making and reducing time spent on iterations.

- Cost Reduction: By minimizing the need for physical prototypes and enhancing early-stage testing, AR helps reduce overall development costs.

- Early-stage Application: AR can be applied during the initial stages of product development, providing valuable insights before committing to physical production.

- Enhanced Safety: AR helps identify and mitigate risks early in the design phase, ensuring safer product development and reducing potential hazards

- Improved Collaboration: Real-time access to AR data fosters enhanced collaboration among teams, business partners, and customers, streamlining communication and decision-making.

- Efficient Product Optimization: AR enables early identification and resolution of design flaws, ensuring a smoother development process and improving product quality.

- Visualization for Stakeholders: AR provides a visual representation of ongoing projects, making it easier to communicate progress and concepts to external departments, partners, and customers.

CONCLUSION

Raygain’s innovative solutions combine Augmented Reality (AR), automation, and cloud technology to enhance operational efficiency and product development. Our platform streamlines manufacturing, maintenance, logistics, and safety processes, offering real-time insights and improving collaboration. By reducing costs, minimizing errors, and accelerating decision-making, Raygain helps businesses optimize workflows, improve product quality, and stay competitive in today’s fast-evolving market.