OVERVIEW

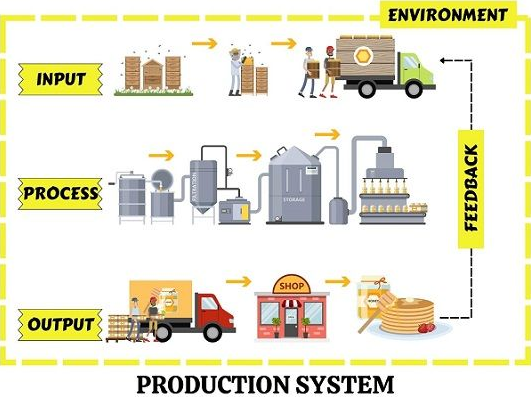

A Production Management System (PMS) serves as a cornerstone for driving operational excellence within manufacturing and production-intensive organizations. It is a sophisticated, enterprise-level solution tailored to enhance the efficiency, accuracy, and scalability of production processes. By consolidating critical functions into a centralized platform, a PMS empowers organizations to synchronize production capabilities with overarching business strategies, thereby ensuring sustained competitiveness in dynamic markets.

KEY FEATURES OF PMS

- Strategic Production Planning: Supports advanced scheduling and capacity planning to align production activities with business goals, ensuring on-time delivery and cost efficiency.

- Resource Optimization: Enhances the utilization of assets, including machinery, materials, and labor, reducing downtime and minimizing waste.

- Operational Visibility: Offers real-time monitoring and reporting on production metrics, enabling data-driven decision-making and proactive issue resolution.

- Quality Control Integration: Incorporates quality management protocols to maintain product standards, ensuring compliance with regulatory and customer requirements.

- Cross-Functional Integration: Connects seamlessly with Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Customer Relationship Management (CRM) systems, fostering a cohesive ecosystem for end-to-end operational excellence.

- Scalability and Adaptability: Provides flexibility to scale operations and adapt to dynamic market conditions or production demands, ensuring business continuity and competitive advantage.

FUNCTIONAL SPECIFICATION FOR PMS

- Display Screen Features:

- Rotating Display: Cycles through data cells every 12 seconds for continuous visibility.

- Line Status Indicator:

- Yellow: No input for 5 minutes (inactivity).

- Green: Line operational.

- Red: Line stopped.

- User Authentication:

- Secure login with user credentials to ensure data integrity and prevent unauthorized access.

- Administrative Control:

- Only admin users can modify REPORT, SETTINGS, CONFIGURATION, and EMAIL modules.

- Report Generation and Export:

- Reports can be generated by selecting a date and exporting via the EXPORT button.

- Email Reporting:

- Reports can be emailed to pre-configured recipients for streamlined communication.

Report Generation Overview

The Production Management System (PMS) supports the generation of key operational reports, including:

- Daily Performance Reports: Detailed daily production analysis.

- Monthly Performance Reports: Executive summaries of monthly KPIs.

- O.E.E. Reports: Evaluation of equipment effectiveness (availability, performance, quality).

- Workforce Utilization Reports: Insights into labor productivity and resource allocation.

- System Utilization Reports: Overview of application performance and user engagement.

- Downtime Reports: Analysis of downtime incidents and their impact.

- Changeover Efficiency Reports: Assessment of changeover durations and optimization opportunities.

- Hourly Production Reports: Real-time production metrics for immediate action.

Strategic Operational Functions

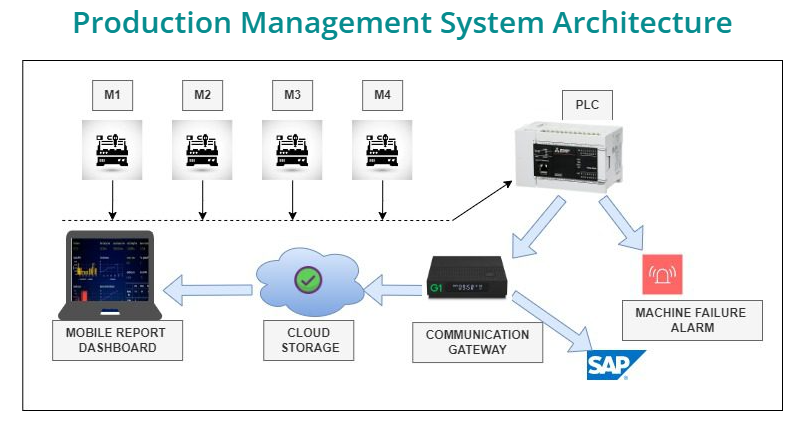

- Production Scheduling and Execution Efficiency:- Real-time production data capture via smart devices for enhanced visibility and operational efficiency.

- Machine Utilization and Downtime Management:- Continuous monitoring of machine utilization, cycle times, and deviations, with automated alerts for machine outages and changeovers.

- Asset Maintenance and Performance Optimization:- Proactive maintenance scheduling and asset usage tracking to extend equipment life and minimize downtime.

- Order Lifecycle Management and Tracking:- Full visibility of orders through seamless integration with SAP, Tally, and Busy, ensuring efficient order management across the shop floor.

- Real-Time Quality Monitoring and Process Control:- Real-time tracking of production quality metrics, enabling effective process control and consistent product quality.

CHALLENGES FACED BEFORE IMPLEMENTING PRODUCTION MANAGEMENT SYSTEM

- Inefficient Production Planning- Manual or fragmented planning processes lead to resource misallocation, delays, and suboptimal scheduling.

- Lack of Real-Time Visibility- Limited access to real-time data hinders informed decision-making and rapid issue resolution during production.

- Operational Silos- Disconnected departments and systems result in poor communication and coordination, reducing overall efficiency.

- High Operational Costs- Inefficiencies in resource utilization, material wastage, and unplanned downtime drive up production costs.

- Inconsistent Quality Standards- Lack of standardized workflows and quality monitoring increases the risk of defective products and customer dissatisfaction.

- Delayed Issue Resolution- Reactive approaches to equipment failures and production bottlenecks lead to prolonged downtime and productivity losses.

- Inaccurate Demand Forecasting- Ineffective integration of sales, inventory, and production data results in overproduction or stockouts.

- Limited Scalability- Traditional systems struggle to adapt to changes in production volume or complexity, restricting business growth.

- Poor Performance Monitoring- Lack of comprehensive reporting and analytics makes it difficult to evaluate productivity, identify inefficiencies, and drive continuous improvement.

- Regulatory Non-Compliance- Difficulty in tracking and documenting processes leads to challenges in meeting industry standards and regulatory requirements.

- Manual Dependency- Excessive reliance on manual processes increases errors, slows operations, and reduces overall productivity.

KEY BENEFITS OF PRODUCTION MANAGEMENT SYSTEM

- Enhanced Equipment Management to improve manufacturing efficiency.

- Optimized Resource Allocation to reduce labor costs.

- Centralized Data Management to eliminate errors and duplication.

- Streamlined Procurement to reduce material costs.

- Improved Planning and Control to reduce work-in-progress times.

- Superior Production Control to ensure consistent output.

- Standardized Procedures for greater operational consistency.

- Faster Accessibility to critical production data.

- Enhanced Monitoring for real-time performance tracking.

- Error-Proofing Mechanisms to increase data accuracy.

- Integrated Systems for seamless operation and full transparency.

- Production Analysis for continuous performance improvement.

Dynamic Production Line Management Ecosystem

- Efficient Line Status Monitoring

- Bottleneck Identification and Resolution

- Accurate Setup Time Tracking

- IoT-Driven Data Logging

- Graphical Representation of Production Line Layout

- Advanced Machine Vision Technology

- Proactive Maintenance Alerts and Notifications

Machine Runtime Optimization System

- Overall Equipment Effectiveness (OEE) Monitoring

- Data Collection and Integration

- Workforce and Operator Utilization Analysis

- Downtime Impact Assessment

- Daily Efficiency Performance Reporting

Efficiency Monitoring and Analysis Tools

- Real-Time Efficiency Measurement

- Comprehensive Downtime Analysis

- High-Speed Production Tracking

- Cloud-Enabled, Application-Based Monitoring

- Automated Report Generation

Additional Features and Enhancements

- Proactive Alarm and Alert Notifications

- Real-Time Fault Diagnostics and Troubleshooting

- Seamless Wireless Connectivity

- Integrated PLC Server with Advanced Analytics

- Automated Email Notifications

- Machine Vision Technology for Surveillance and Monitoring

CONCLUSION

Raygain’s Production Management System (PMS) exemplifies innovation and excellence in delivering cutting-edge solutions for manufacturing efficiency. By combining advanced technology with seamless integration, PMS empowers businesses to optimize operations, enhance productivity, and achieve strategic goals.

With a focus on quality, scalability, and adaptability, Raygain continues to set new benchmarks in enabling organizations to thrive in competitive markets through streamlined production and data-driven decision-making.