Overview

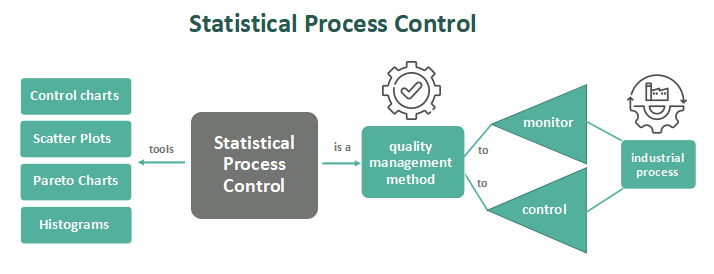

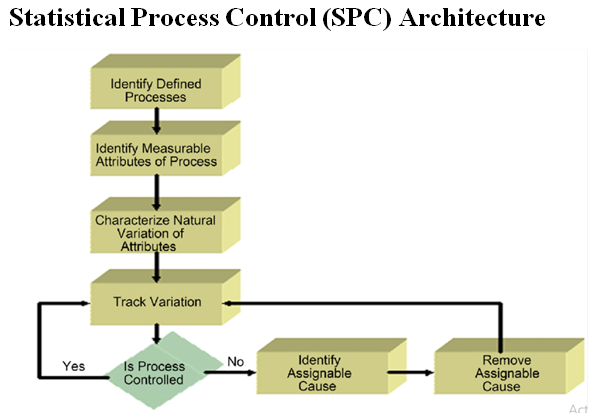

Statistical Process Control (SPC) systems represent a cornerstone of advanced quality management strategies, enabling organizations to achieve unparalleled process consistency and product excellence. By applying sophisticated statistical methodologies, SPC systems proactively monitor and control manufacturing processes, ensuring optimal performance and adherence to stringent quality standards.

Designed to seamlessly integrate into modern production environments, SPC systems provide real-time data acquisition, automated analytics, and actionable insights that empower organizations to reduce variability, enhance efficiency, and mitigate risks.

Key FEATURES

Dynamic Content Delivery: Enables the display of multimedia, including videos, animations, and live feeds, tailored to specific audiences.

Real-Time Adaptability: Offers instant updates and remote management, ensuring timely and relevant messaging.

Improved Customer Experience: Enhances engagement with personalized, visually appealing content and interactive interfaces

Cost-Efficiency: Reduces dependency on print materials, lowering recurring expenses and enabling sustainable practices.

Analytics and Insights: Tracks viewer behavior and engagement to refine communication strategies and improve ROI.

Wide Applicability: Suitable for retail, corporate, healthcare, education, and public spaces, offering diverse use cases like promotions, wayfinding, internal communications, and event updates.

FUNCTIONAL SPECIFICATION FOR STATISTICAL PROCESS CONTROL SYSTEM

- Real-Time Monitoring: Track machine performance and KPIs with live dashboards.

- Advanced Analytics: Perform trend analysis, control charting, and process capability assessments.

- Alerts and Notifications: Immediate deviation alerts for rapid intervention.

- System Integration: Connect seamlessly with IoT, ERP, and MES platforms.

- Customizable Dashboards: Tailor metrics and views for role-specific needs.

- Data Security: Ensure encrypted data transmission and compliance with privacy standards.

- Remote Access: Cloud-based monitoring for anytime, anywhere insights.

CHALLENGES FACED BEFORE IMPLEMENTING STATISTICAL PROCESS CONTROL SYSTEM

- Enhanced Communication: Real-time, consistent, and targeted messaging.

- Increased Engagement: Captures attention with dynamic and interactive content.

- Cost Efficiency: Reduces printing costs and enables centralized content updates.

- Brand Consistency: Ensures uniform messaging across all locations.

- Real-Time Updates: Instant adjustments with live data integration.

- Data Insights: Analytics for measuring engagement and optimizing strategies.

- Scalability: Easily expands across locations with minimal resources.

- Sustainability: Lowers environmental impact by reducing paper usage.

BENEFITS OF STATISTICAL PROCESS CONTROL SYSTEM

- Quality Enhancement & Traceability: Ensures higher product quality and complete traceability, minimizing defect rates through continuous monitoring.

- Process Automation: Streamlines operations, reducing manual errors with automated data collection and real-time analysis.

- Regulatory Compliance & Operational Excellence: Guarantees adherence to industry standards while fostering operational efficiency and excellence.

- Scalable & Configurable Architecture: Provides flexible, scalable solutions tailored to diverse production needs and environments.

- Centralized Data Analytics Hub: Delivers an integrated platform for centralized data management and advanced analytics.

- Customizable Data Storage Solutions: Offers scalable data storage options with customizable configurations based on client requirements.

CONCLUSION

Raygain’s Statistical Process Control (SPC) system delivers unmatched operational efficiency, superior product quality, and regulatory compliance. By integrating real-time data acquisition, advanced analytics, and actionable insights, our solution minimizes variability, enhances process consistency, and reduces downtime.

With flexible, scalable, and customizable features, Raygain empowers businesses to make data-driven decisions, improve traceability, and optimize production. Our SPC system supports continuous improvement, ensuring that your operations meet and exceed industry standards, while fostering long-term growth and profitability. Choose Raygain for a future of operational excellence and sustainable success.