VDIS

Overview

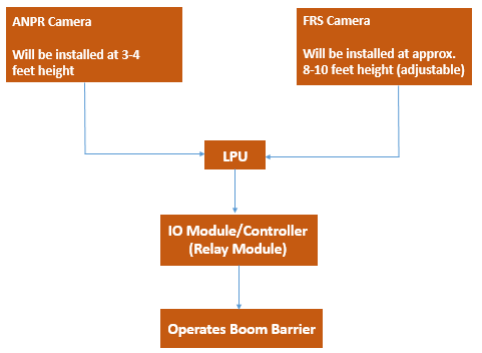

A robust system that integrates Automatic Number Plate Recognition (ANPR) and Facial Recognition System (FRS) for secure and automated access control. The system will identify and verify the driver by matching the detected face with the registered vehicle number plate. Upon successful verification, the system will operate the boom barrier to allow entry.

Key FEATURES:

- Configuration Customization: This feature allows detailed customization of RFID tag information for each workman. It also provides the flexibility to set limits for idle time and alerts for crossing designated boundaries (geo-fencing violations)

- Geo-Fencing Capabilities: Administrators can set geo-fencing zones for each workman, and the system will generate alerts if anyone crosses these boundaries based on the set rules.

- Real-Time Monitoring Panel: The system includes a real-time monitoring panel with a map interface that shows the location of each workman, along with real-time headcount for each zone and the entire plant. It also provides a quick summary of zone-wise headcount, active, and inactive tags, making it easy to track workmen and their activities.

- Historical Dashboard Analysis: A historical dashboard allows the selection of individual workmen and specific days for tracking their routes and reviewing their activities. This feature provides detailed insights into past movements and patterns

FUNCTIONAL SPECIFICATION FOR VDIS

Data Processing and Verification

- The system processes the captured vehicle number plate and facial image, cross-checking both with a pre-registered database of authorized vehicles and personnel. ANPR matches the license plate, while FRS verifies the driver’s face with registered users in the system.

Dual Authentication:

- The system verifies that both the vehicle’s number plate and the driver’s face match the registered data. If both checks are successful, it signals the boom barrier to open, allowing entry.

Failed Authentication:

- If the vehicle’s number plate or driver’s face does not match the database, the barrier stays closed. In case of a mismatch or unrecognized vehicle/person, an alert is triggered, notifying security personnel for further investigation or manual approval.

Real-Time Monitoring and Logs:

- The system continuously monitors vehicle and personnel entries and exits in real time, maintaining a log of all events, including images of the vehicle’s number plate, the driver’s face, entry/exit times, and any triggered alerts.

CHALLENGES FACED

Challenges without a real-time tracking solution:

- Delayed Emergency Response: In case of an accident, finding where workers are and how many are in a specific area is difficult, which slows down emergency response and rescue efforts.

- Safety Risks: If someone enters a restricted zone without permission, it can cause safety problems, accidents, and break security rules.

- Compliance Problems: High-security zones have strict rules for who can enter and how people are tracked, but without an automatic system, it’s hard to enforce these rules, leading to problems with following regulations.

- Poor Resource Management: Without knowing where workers are, it’s hard to assign tasks efficiently. This can cause delays in work and misuse of manpower.

BENEFITS OF VDIS

- Enhanced Safety and Security: Prevents unauthorized access to restricted areas, reducing safety risks.

- Improved Emergency Response: Provides real-time location data for quicker identification of workers during emergencies.

- Increased Operational Efficiency: Enables effective resource allocation and task management, boosting productivity.

- Data-Driven Decision Making: Offers insights into worker movements to optimize processes.

- Regulatory Compliance: Maintains accurate records of worker movements for adherence to safety regulations.

- Enhanced Accountability: Increases visibility of worker activities, allowing for quick identification of task deviations.

- Cost Savings: Reduces incidents and improves management, leading to long-term savings.