INDUSTRY 4.0

INDUSTRY 4.0

Raygain having subject matter expert & solution for industry 4.0. Industry 4.0, often referred to as the Fourth Industrial Revolution, represents the integration of smart technologies into manufacturing and production systems. It leverages advancements in connectivity, automation, and data to create more efficient, flexible, and intelligent manufacturing processes.

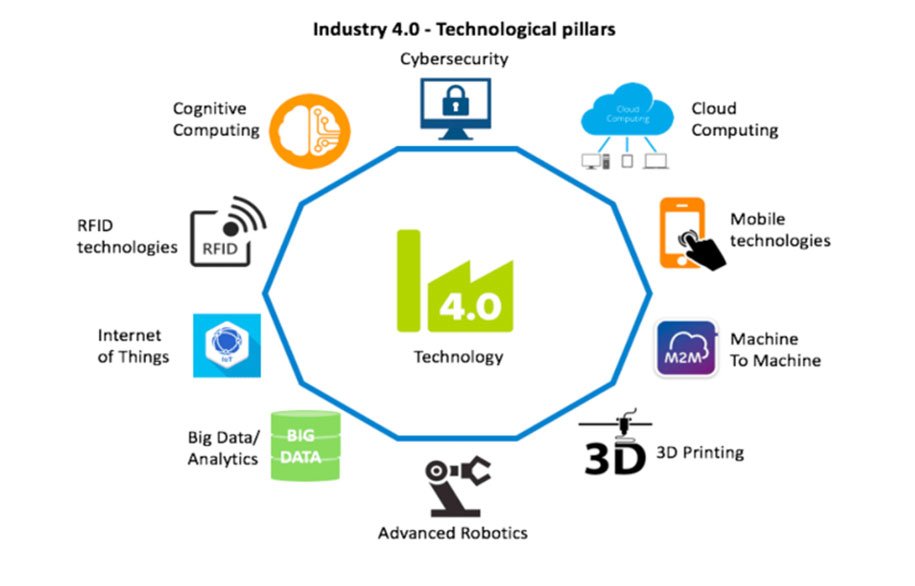

Key Pillars of Industry 4.0:

- Internet of Things (IoT): Connecting machines, devices, and systems to collect and share data.

- Artificial Intelligence (AI) & Machine Learning: Using data analytics to optimize operations, predict failures, and enable autonomous decision-making.

- Big Data & Analytics: Managing and analyzing large volumes of production data to uncover trends and improve efficiency.

- Cyber-Physical Systems (CPS): Integration of physical and digital systems for real-time interaction.

- Cloud Computing: Providing scalable and secure data storage and access solutions for industrial applications.

- Augmented Reality (AR) & Virtual Reality (VR): Supporting training, maintenance, and design processes.

- Additive Manufacturing (3D Printing): Enabling customized production and reducing waste.

- Digital Twin Technology: Creating virtual models of systems to simulate and optimize performance.

- Robotics and Automation: Enhancing precision and efficiency through automated systems.

- Cybersecurity: Ensuring the protection of connected devices and networks against potential threats.

Benefits

- Increased operational efficiency.

- Enhanced product customization and innovation.

- Reduced downtime with predictive maintenance.

- Better resource management and energy efficiency.

- Improved supply chain transparency.

Challenges:

- High implementation costs.

- Need for workforce reskilling and training.

- Data security concerns.

- Complexity of integrating new technologies with legacy systems.

VDIS

Vehicle Driver Identification System

Smart Helmet

A smart helmet with a 5G camera is more than just protective gear

Connected workers

The Connected Worker System operates within a

PSV

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

Digitization of M&I practices

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

Push To Talk

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

Connected Machinery

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

Drone Surveillance

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

Image processing

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

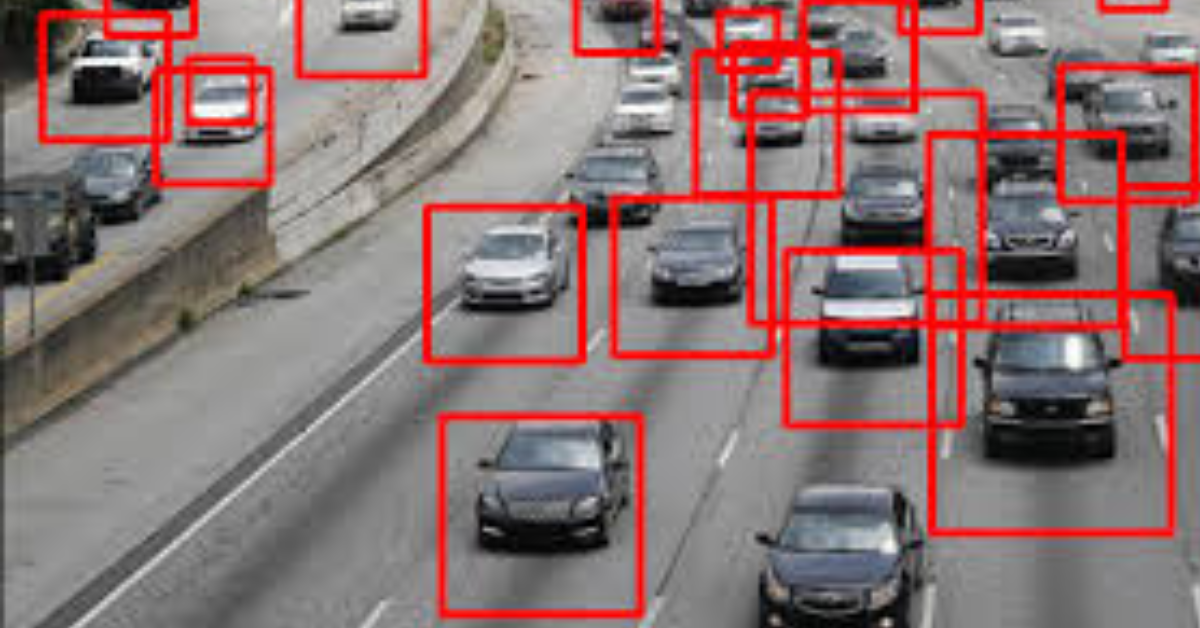

Video Analytics

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

Vibration process for Rotary Equipment

Do you know the Elementor image box height? Offering the best image box wordpress plugin.

vechicle monitoring system

Do you know the Elementor image box height? Offering the best image box wordpress plugin.