Introduction:

What is Industrial Automation

Industrial Automation revolutionizes manufacturing and production sectors . Industrial automation is where use of control systems, robots, computer and information technologies is used to handle different process and machines to handle tasks. Technologies like robotics, PLC , sensors and AI integrates in industrial operation so that it can perform human tasks , it can minimizes error and boosts productivity.

Benefits Of Industrial Automation

- Enhanced Efficiency

Automated system improved efficiency as it can work 24*7 leading to increased throughput , machines perform complex tasks fast and with more accurate precision leading to better and right result. - Cost Reduction

Automation decreased downtime caused by human error , the long term saving on automated system is in profit as it reduces and save labor cost , waste reduction. - Improved Quality Control

Advanced sensors and monitoring systems can detect defects at early stage and corrected in real- time results in quality products it will ensure better production process. - Safety in the Workplace

In extreme conditions, handling overload and toxic material are easily done by robots than human , it minimizes risk of injuries and accidents. - Scalability and Flexibility

Modern automation solutions can adapt to varying production needs, making it easier for industries to scale operations or switch between different product lines efficiently.

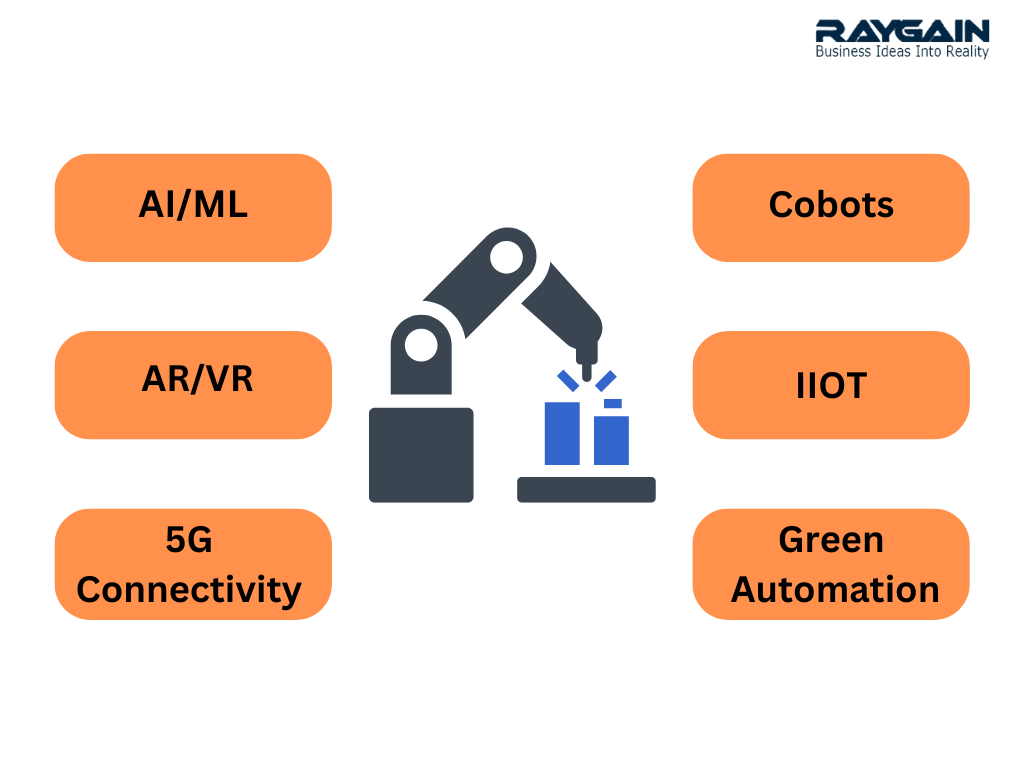

Next Gen of Industrial Automation:

- Artificial Intelligence and Machine Learning

- Industrial Internet of Things (IIoT)

- Collaborative Robots (Cobots)

- 5G Connectivity

- Augmented Reality (AR) and Virtual Reality (VR)

- Green Automation

Artificial Intelligence and Machine Learning:

Through AI/ML machines learns from past data improve and learn with time and enhances operations .AI/ML results in smarter automation systems that can analyse data , predicts defects and maintenance.

Industrial Internet of Things (IIoT)

To avoid downtime, track performance metrics and implementing strategies of predictive maintenance the IIoT connects devices and machines to a network, enabling seamless data exchange.

Collaborative Robots (Cobots)

Cobots are designed to work alongside humans, enhancing productivity while ensuring safety. Unlike traditional robots, cobots are highly flexible and can be programmed easily to perform various tasks, making them ideal for small and medium enterprises.

5G Connectivity

The performance of real-time monitoring systems, autonomous vehicles, and remote-controlled operations enhance with the deployment of 5G networks as it provides fast and ultra reliable communication.

Augmented Reality (AR) and Virtual Reality (VR)

To guide trainers and technician AR and VR technology is used in industrial automation .These can be integrated in training and maintenance . AR glasses use in providing instructions while working on machinery.

Green Automation

Sustainability is becoming a priority. The next generation of automation will focus on energy-efficient systems, waste reduction, and renewable energy integration, aligning with global environmental goals.

Real – world Examples:

Automotive Industry: Tesla’s Smart Manufacturing

Tesla has revolutionized the automotive sector through automation. Its factories utilize advanced robotics and AI-powered systems to assemble vehicles with minimal human intervention. The use of Cobots ensures precision and speed while allowing seamless collaboration with human workers. Furthermore, predictive maintenance enabled by IIoT sensors minimizes production downtimes and enhances operational efficiency.

Retail Industry: Amazon’s Fulfillment Centers

Amazon’s warehouses leverage a combination of robots, AI, and IIoT to optimize inventory management and order fulfillment. Automated systems handle sorting, packing, and transportation of goods, significantly reducing order delivery times. These smart systems have also enhanced workplace safety by reducing human involvement in hazardous tasks.

Conclusion:

Industrial automation has transformed the manufacturing and production industries, fostering advancements in efficiency, quality, safety, and flexibility. The adoption of cutting-edge technologies such as robotics, AI/ML, IIoT, and 5G has propelled industries into a new era of innovation. Companies leveraging these advancements are not only reducing costs but also enhancing sustainability, thereby aligning with the evolving demands of modern businesses and global ecological goals.